Body:

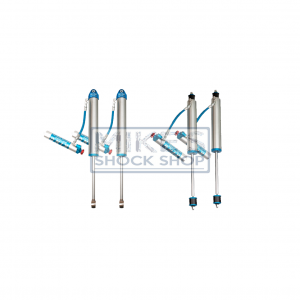

Shock cylinders are bored and honed after cadmium plating to ensure cylindricity and an efficient piston seal that enhances valve function.

Components:

Highly developed port designs on our 6061 aluminium alloy piston provide the famous King ride quality.

Shaft:

Large ¾” or 7/8” diameter shafts have a tensile strength of 100,000 pounds per square inch. They are hard chromed to combat rock bruising and micro-polished to a 6 RA finish for extended seal life.

Piston:

Shocks cylinders are precision bored within x/- .001 then honed after zinc plating to remove buildup for a tight piston seal and optimum valving function.

Seals:

Special long wearing urethane seals have been tested on 18 wheelers for 450,000 miles without a failure.

Valving:

Heat treated stainless alloy valve shims do not fracture like plain carbon steel and resist deformation at high temperatures providing consistent fade free performance.

Wear bands are made from a Rulon composite that offers incredible wear resistance, low deformation under load and high compressive strength. Overlapping end design enhances sealing.